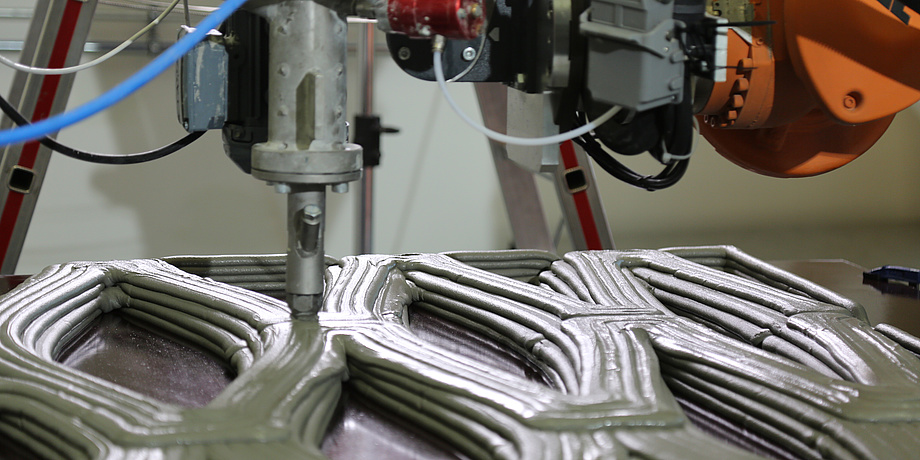

But work is being done at TU Graz on additive manufacturing of concrete parts using printing robots.

“Everything began with a curious student,” recounts Andreas Trummer from the Institute of Structural Design at TU Graz. “One of our students had heard about 3D concrete printing and wanted to explore this in depth in his master’s thesis. Jürgen Holl – at the time doing his master’s in architecture – used the Institute’s ABB robot lab to develop a prototype of a conveyor and 3D printing plant. He spent hours and days researching the mysteries of concrete printing. And then the Institute asked itself an even bigger question: how can this completely new technology be used in the building industry?

“In some areas the building industry has hardly changed over the last few decades,” explains Stefan Peters, head of the Institute of Structural Design. “The procedures by which buildings are made today hardly differ from those I got to know as a young person in my holiday jobs on building sites. The COEBRO project (Additive Fabrication of CONCRETE ELEMENTS BY ROBOTS) was launched in 2015 out of the desire to create something new in the field. It is funded and supported by the Austrian Research Promotion Agency (FFG) and partners from science and business through the Bridge programme.

Read more about the COEBRO project, how it specialises in the production of prefabricated concrete parts and why this research will conserve resources in the News+Stories article on the TU Graz website.