From the outside, the two new white cabinets are inconspicuous. Rather big. White. Each one with a viewing window and a sample stage. But the unspectacular exterior is deceptive. The cabinets contain two powerful micro-CT chambers initiated by the inter-university Graz-µCT consortium (TU Graz, Uni Graz and MedUni Graz) and funded by the Austrian Research Promotion Agency – FFG. "With these devices, we can look deeply into the material structure of a sample without destroying the sample," explains Eduardo Machado Charry. The senior scientist at TU Graz is responsible for the equipment, prepares the samples and designs the experiment set-ups. In addition, he also partly takes care of the data analysis afterwards – an incredible amount of work, as Robert Schennach, researcher at the Institute of Solid State Physics and head of the consortium, explains. "You have to imagine, each of our measurements produces enormous amounts of data. Several gigabytes of data have to be processed per test."

But how does this data actually come about? Depending on the research question, different experiment set-ups have to be designed. As an example, the researchers want to investigate the effects of water on paper at different moisture stages. "With our micro-CTs, we can measure in situ with high temporal resolution," explains Robert Schennach. To do this, however, the required amount of water must be brought inside the unit and the process must run – a challenge to the experiment design that must first be overcome.

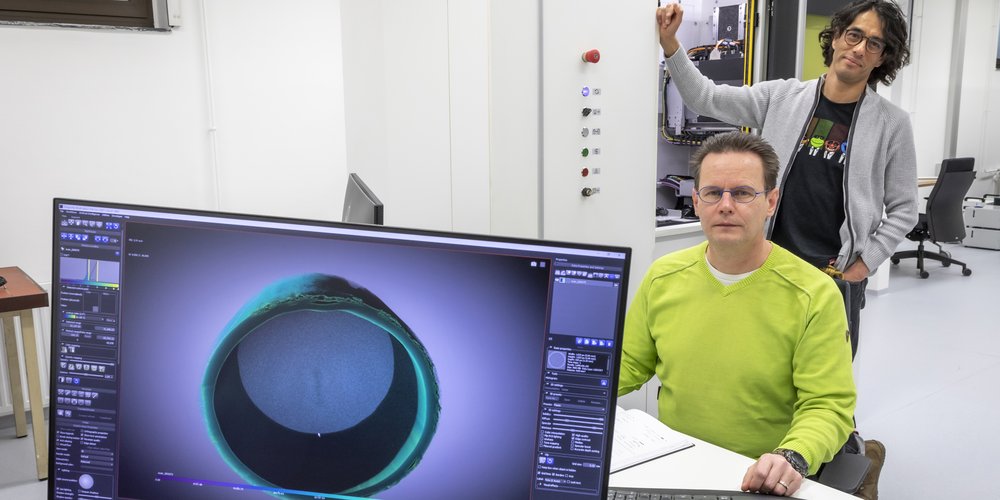

But basically, “Each material sample is mounted on a rotating sample holder and spins while being bombarded with X-rays. This gives us a three-dimensional image of the sample that can be visualized on the computer and allows us to look into the material structure," explains Machado Charry.

The two devices – Tescan UniTom HR and XL – examine the material samples non-destructively and thus complement other measurements wonderfully, for example with electron microscopes. "The electron microscopes admittedly achieve a higher resolution. Our devices stop at approx. 800 nanometres. But our measurements are wonderfully suitable for getting an overview of the structures and preparing, for example, the expensive investigations at a synchrotron." Samples such as concrete, paper and rock can be examined, as well as biological materials. "Biological materials are of course damaged by X-rays to some degree – no method is perfect, but at least we’re getting close," says Machado Charry with a smile. Measurements can take a few minutes or several days – so far the researchers have limited themselves to measurements of around six hours.

In any case, the laboratory box with material samples is well stocked. For example, volcanic rock is currently being investigated together with the Austrian Centre for Electron Microscopy and Nanoanalysis (FELMI-ZFE), new concrete compositions with the Institute of Technology and Testing of Construction Materials, including changes to concrete pipes and charging and discharging processes in batteries.

Trials are currently being implemented mainly by the 13 partner institutes of the consortium. "But we also allocate time for experiments with external partners and are happy to look at new research questions," says Robert Schennach, inviting other research institutions and companies to collaborate.

This research area is anchored in the Field of Expertise “Advanced Materials Science”, one of five strategic foci of TU Graz.

You can find more research news on Planet research. Monthly updates from the world of science at Graz University of Technology are available via the research newsletter TU Graz research monthly.

Contact:

Robert SCHENNACH

Ao.Univ.-Prof. Mag. Dr.rer.nat.

Petersgasse 16/II

8010 Graz

robert.schennach@tugraz.at

https://www.tugraz.at/projekte/gmct/home/